Sustainable and Environmentally-Conscious Options in litho printing

Sustainable and Environmentally-Conscious Options in litho printing

Blog Article

A Comprehensive Guide to Understanding Litho Printing Methods

The world of litho printing, a technique stemming from the late 18th century, is an interesting mix of background, art, scientific research and advancement. Keep with us as we journey right into the captivating realm of litho printing.

The Historical Advancement of Litho Printing

The historic trajectory of litho printing, an essential development in the realm of interaction, is a fascinating tale of human resourcefulness. Birthed in the late 18th century by Alois Senefelder, this strategy was initially a cost-effective technique of publishing theatrical works. Lithography, originated from the Greek words for 'stone' and 'to compose', used a smooth stone surface to transfer pictures onto paper. The process developed with the arrival of the rotating press, which significantly raised efficiency (litho printing). In the 20th century, the technology of countered lithography reinvented the market, permitting mass production of high-quality prints. Each stage of litho printing's evolution showcases humanity's unrelenting search of efficiency and quality in visual interaction.

Decoding the Scientific Research Behind Litho Printing Inks

Moving on in the expedition of litho printing methods, the focus currently changes to the science behind litho printing inks. The make-up of these inks, their drying procedure, and color mixing strategies form the backbone of this complicated art form. Recognizing these aspects is essential to mastering the craft and attaining the preferred print outcomes.

Structure of Litho Inks

In lithographic printing, the basic function of litho inks can not be overstated. Pigments, the color-providing components, are carefully ground fragments suspended in the car, a liquid that lugs the pigment onto the printing surface. Each part plays a crucial component in the final print's top quality, making the accurate formulation of litho inks an intricate scientific research.

Ink Drying Process

From the make-up of litho inks, attention turns to the fascinating procedure of ink drying out. The drying out procedure is critical, as it influences the final print's high quality and long life. Two primary techniques are used in litho printing: oxidative drying and absorption. Oxidative drying out entails the ink reacting with oxygen in the air to create a hard, completely dry movie. This method supplies a long lasting coating, yet can be slower compared to absorption. Absorption, on the various other hand, includes the ink seeping right into the paper fibers, which is a quicker procedure however can bring about less dynamic colors. The selection between these methods depends on aspects such as print speed needs, the paper kind made use of, and the preferred coating.

Shade Combining Methods

While the drying process plays a key function in litho printing, the scientific research of color blending techniques holds equivalent significance. This is a complicated process that includes the cautious mixing of key colors: cyan, magenta, and yellow, in differing percentages to accomplish a large selection of colors. The addition of black ink, recognized as 'crucial', aids in managing the intensity and depth of the shades. The scientific research behind litho printing inks additionally takes right into account the transparency of the ink, which influences just how colors overlay and mix. To achieve an effective shade mix, print specialists must additionally comprehend the intricacies of ink actions, color theory, and the physical properties of the substrate on which the ink is applied.

The Art and Layout Components in Litho Printing

Litho printing breathes life into art and style via its unique elements. Litho printing fits a variety of colors, making it possible for artists to create click for more info vibrant and lively prints. This combination of accuracy and adaptability makes litho printing a favored option for several musicians and designers.

Modern Applications of Litho Printing Strategies

Litho printing techniques have located considerable use in the contemporary business sector. Its impact and value remain to expand with the introduction of new advancements and modern technologies in the area. This area will explore these contemporary applications and the transformative duty they play in the printing industry.

Commercial Litho Printing Makes Use Of

Litho printing stays an important part of the business sector. High-volume printing jobs, such as the manufacturing of publications, papers, and product packaging, count on litho printing for its capacity get more to deliver premium photo high quality and price effectiveness. Litho printing likewise gives a broad shade spectrum, exceptional to that of digital printing.

Advancements in Litho Printing

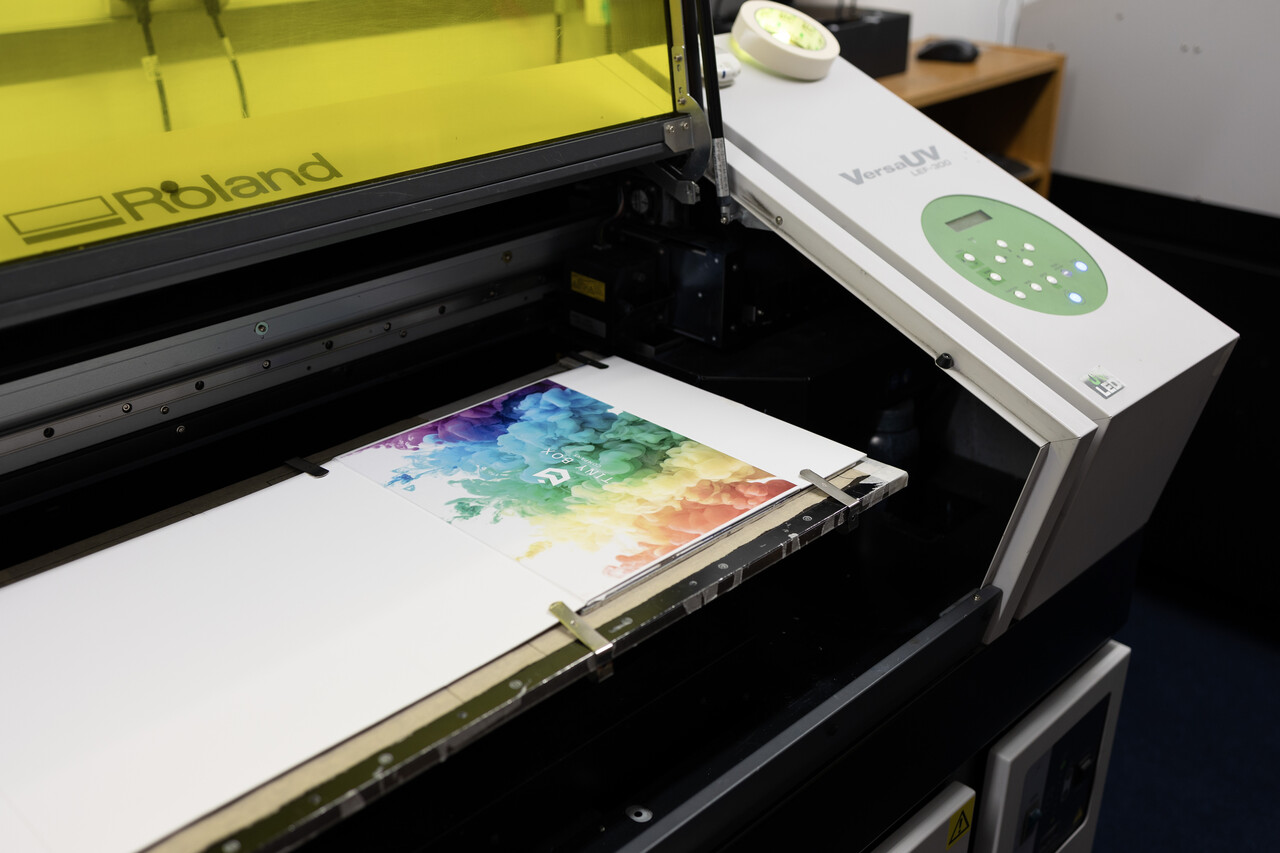

Pressing the borders of standard methods, contemporary improvements have actually sustained a host of developments in litho printing. These advancements have not just improved the quality and efficiency of litho prints but additionally increased its application range. One famous development is digital litho printing, which incorporates the virtues of electronic modern technology with litho's premium outcome. This crossbreed version offers faster arrangement times, decreased waste, and enables on-demand printing. An additional noteworthy advancement is the intro of ecologically friendly inks. These inks, made from veggie or soy-based solutions, have considerably lowered the sector's environmental impact. litho printing. In addition, the development of advanced plate technology has streamlined the printing procedure, causing sharper images and improved shade fidelity. These developments emphasize the long-lasting significance of litho printing in the contemporary world.

Discovering the Process of Litho Printing: Action by Action

Difficulties and Solutions in Contemporary Litho Printing

Despite the accuracy and tradition that litho printing proudly promotes, it is not without its look at here collection of contemporary obstacles. Digital litho printing allows for economical brief runs and very easy customization, attending to the concern of variable information. Thus, while there are obstacles, the litho printing industry is proactively adjusting to fulfill them head-on, ensuring its importance in the future.

Conclusion

In conclusion, litho printing, with its abundant background and clinical details, holds a significant area in the print sector. The future of litho printing pivots on its ability to adjust to these transforming demands, verifying its enduring worth in an evolving market.

Report this page